The concept of steam-based fabric care dates back centuries, with early forms of steaming used to smooth textiles through the application of hot steam generated by boiling water. However, these traditional methods were manual and often cumbersome.

The Vertical electric steamers appeared in the mid-20th century as electricity became widely accessible in homes. Early models were bulky and primarily used in commercial settings such as dry cleaners or garment factories. These machines focused on functionality rather than portability or aesthetic design, relying on basic heating elements and large water reservoirs to generate steam.

Vertical steamers emerged as a solution to simplify fabric care by allowing users to steam garments in an upright position. This design was especially convenient for delicate fabrics or clothes that were difficult to iron flat.

As technology advanced, so did the design of vertical electric steamers. The following key improvements marked the progression from past to present:

Compactness and Portability: Early vertical steamers were heavy and stationary. Over time, manufacturers developed smaller, lighter models with detachable water tanks, making them more user-friendly for home use.

Improved Heating Elements: Modern steamers incorporate efficient heating systems that heat water faster and produce continuous steam output. This reduces waiting time and enhances performance.

Adjustable Steam Settings: Today's vertical steamers often feature adjustable steam levels to accommodate different fabric types, from delicate silks to heavy cottons.

Enhanced Safety Features: Modern units include automatic shut-off mechanisms, overheat protection, and insulated handles, which were less common or absent in earlier models.

Aesthetic and Ergonomic Design: Sleeker shapes, ergonomic handles, and easy-to-use controls reflect consumer preferences for stylish and comfortable appliances.

Several technological advancements have contributed to the improved efficiency and appeal of vertical electric steamers:

Rapid Heat-Up Technology: Newer models can generate steam in as little as 30 seconds, increasing convenience for busy users.

Continuous Steam Function: Advanced steamers maintain a consistent flow of steam, enabling more effective wrinkle removal.

Anti-Calc Systems: Built-in anti-scale features help prevent mineral buildup, extending the steamer's lifespan and reducing maintenance.

Multi-Functionality: Some vertical steamers now come with attachments for different purposes, such as fabric brushes or crease tools, expanding their usability.

Vertical electric steamers have transitioned from niche commercial equipment to essential household gadgets. Their versatility appeals to various user groups:

Home Users: People use vertical steamers to quickly refresh clothes, curtains, upholstery, and even bedding, avoiding the hassle of traditional ironing.

Travelers: Portable travel steamers, a compact subset of vertical steamers, provide wrinkle care on the go, catering to frequent travelers and business professionals.

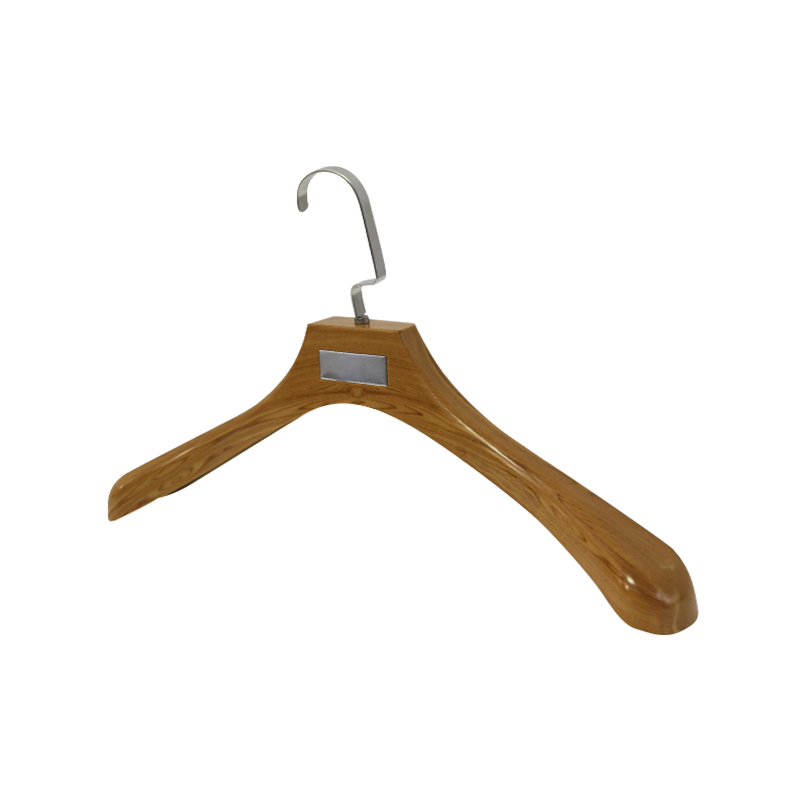

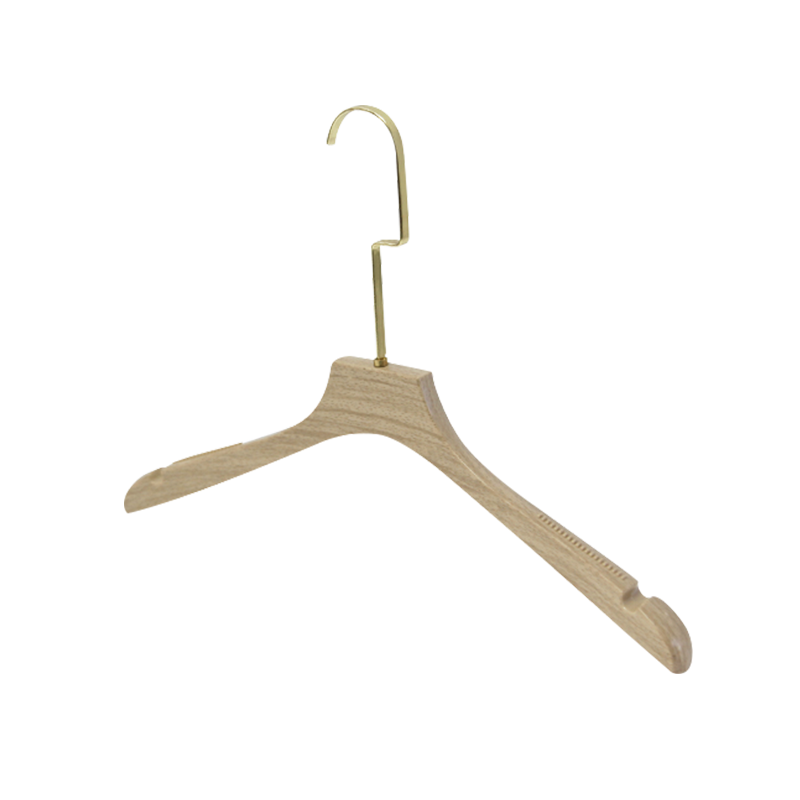

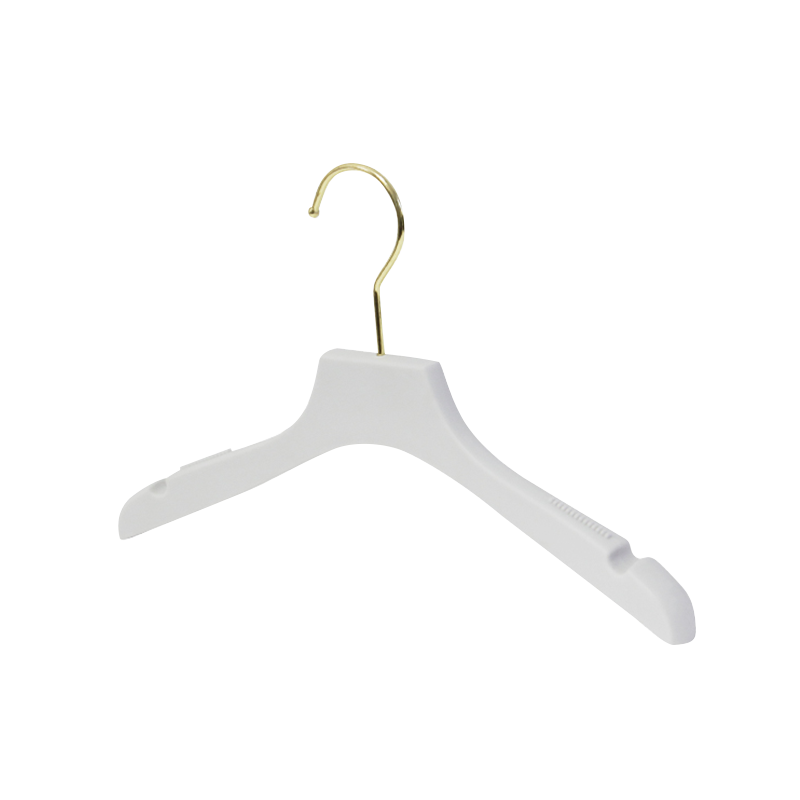

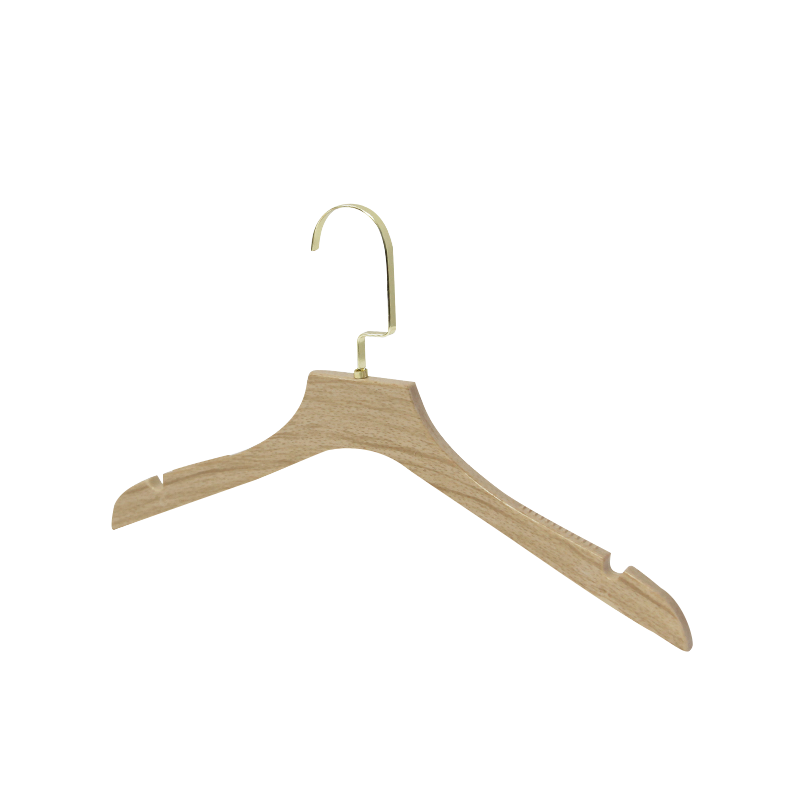

Fashion Industry: Designers and retailers use high-end vertical steamers for fabric preparation and garment display.

Hospitality Sector: Hotels and restaurants employ vertical steamers to maintain staff uniforms and linens efficiently.

Vertical electric steamers offer several benefits compared to traditional ironing:

Energy Efficiency: Steamers generally consume less energy due to shorter heat-up times and reduced operational complexity.

Fabric Care: Steaming is gentler on fabrics, reducing wear and extending garment life.

Convenience: Upright steaming eliminates the need for ironing boards and allows for quick touch-ups.

These advantages align with modern lifestyle demands for efficiency and sustainability.

Despite their progress, vertical electric steamers face challenges such as:

Water Capacity Limitations: Many models require frequent refilling for extended use.

Performance on Heavy Fabrics: Steaming thick or heavily wrinkled fabrics can sometimes be less effective than ironing.

Looking ahead, manufacturers are focusing on:

Increasing Water Tank Size: To allow longer continuous use without interruptions.

Smart Features: Integration of IoT technology for personalized steaming settings and maintenance alerts.

Eco-Friendly Materials: Use of sustainable materials in design and packaging.

Language

Language  English

English 中文简体

中文简体 Español

Español русский

русский